Foundation of the month: qinu

02.08.2022

Philipp Hauff

Founder of the month

This month we introduce you to the team at qinu. They have an exciting development story that culminated in their founding in March 2021.

What does your company stand for?

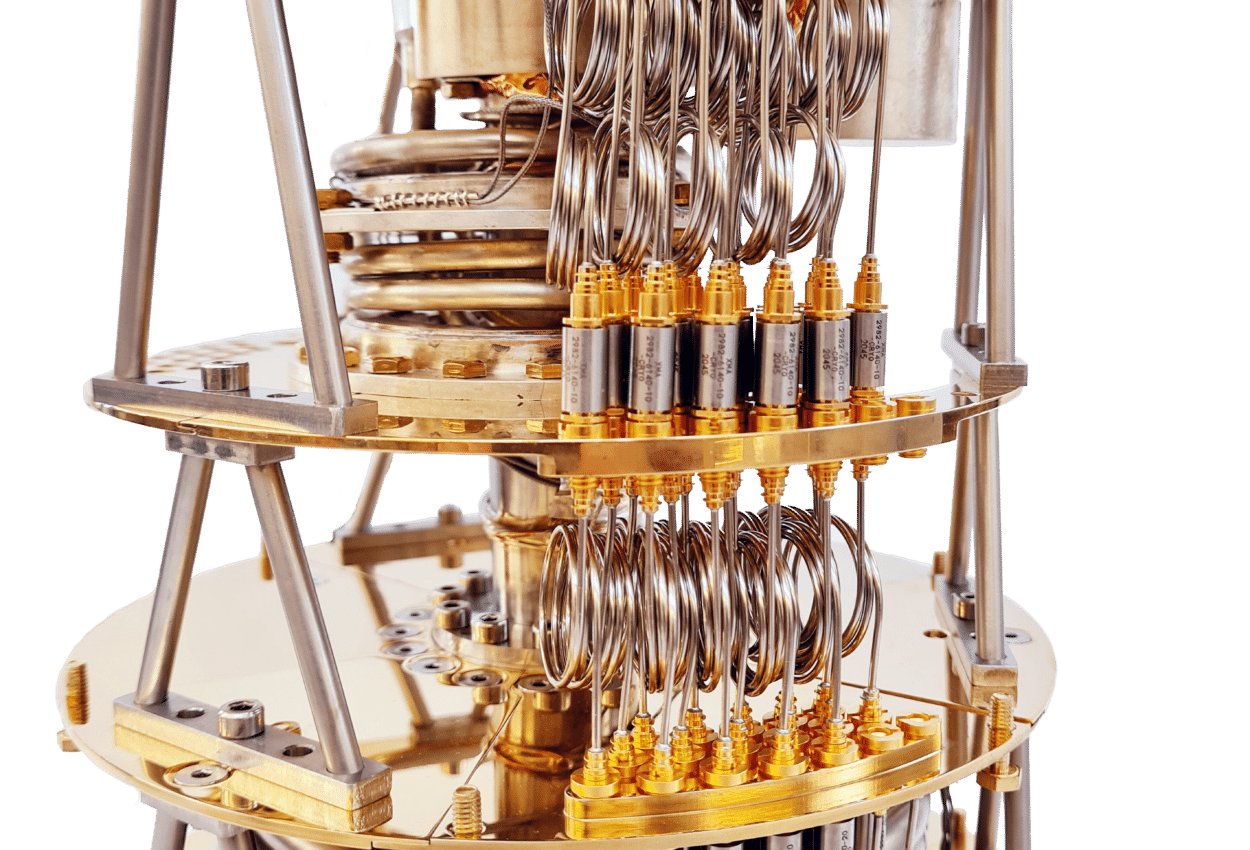

qinu is a company that develops and manufactures high-tech systems for industry and research. Without going into too much detail, these are exceptional cooling systems that can generate extreme conditions such as very low temperatures (0.01 °C above absolute zero) and vacuum, as well as provide protection from electromagnetic radiation. In the past, these so-called dilution cryostats were used primarily in basic research. Due to emerging quantum technologies such as quantum computing, quantum sensing, and quantum communications, there is now increasing demand in new branches of research and also in broader industry. Our Qinu systems feature high cooling efficiency, very compact design and extremely fast cooling times, visibly differentiating them from our competitors’ systems. Our aim is to provide industry and research with a platform on which they can realize their individual technologies in the best possible way.

Where and how did you come up with the bright idea for the foundation?

qinu itself was founded in March 2021 and is thus just over 1 year old, but our systems have a much longer development history. Starting in Grenoble (France), this type of cryostat was further developed and optimized over many years. Our co-founder Wolfgang Wernsdorfer was heavily involved in this process, with his PhD supervisor having developed the original design. However, the cryostats never moved out of research during this time and were only developed and used in close research collaborations. When Wolfgang came to KIT 6 years ago, he brought his know-how and some systems with him. Over the years, through contact with other researchers, we became more and more aware of the need for such a cryostat in research and industry and the potential behind it. We founders thus got together and looked at how we could manage this transfer from research to industry and which hurdles all had to be overcome in order to set up a company.

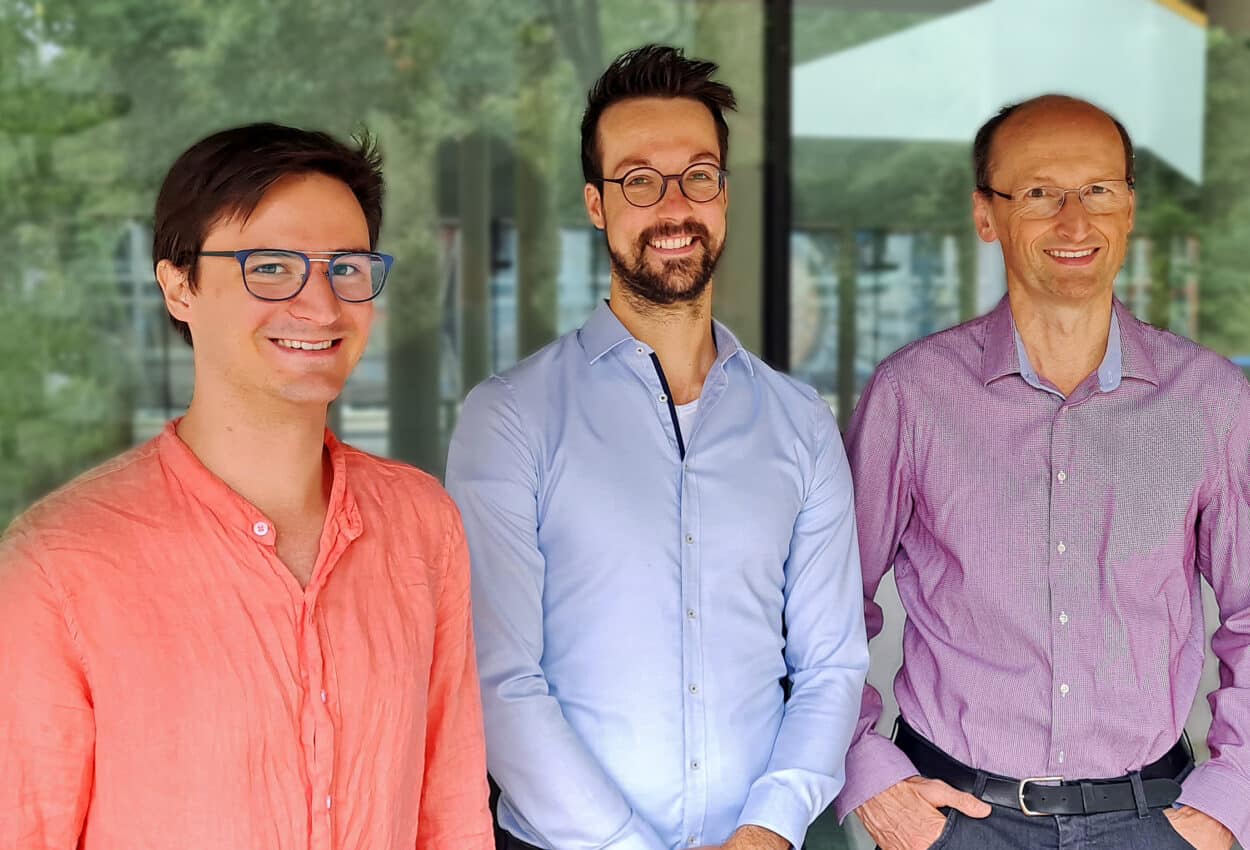

How did the founding team come together?

We three founders met in the research group of Wolfgang and know each other now for many years. Since in the research group the systems were already used and manufactured in a previous version, we all had a lot of practical experience with manufacturing, but also with the procurement of the individual parts, etc., before the foundation.

Where do you see the hurdles in the founding process? Where did you get support?

To commercially realize a product from research and bring it to market, there are many questions and uncertainties at the beginning. What was the first big hurdle for us in this sense, was the information procurement. It was important for us to understand exactly what research transfer options are available and what advantages and disadvantages they have. Once it was clear that we wanted to do this independently via a startup, it was important to clarify how to start a company in the first place, what financing methods are available, and more. Here we have taken support, where we could only. Advisory centers in the KIT environment were helpful, but the various chambers of industry and commerce also provided a good basis for information and advice. Especially helpful for us were meetings and discussions with young founders themselves.

What was one of your greatest challenges during the start-up phase?

Our products are complex technical systems with an average delivery time of 6-7 months. Accordingly, manufacturing management and production planning was and still is very challenging for us. From the establishment of a stable supply chain to the transfer of manufacturing knowledge from the founders to the first employees, there are many small challenges in the process, especially in the days of Corona. We have made great progress here over time, but we still see potential for optimization after one year.

Has Corona had an impact on your startup/industry so far, and if so, what?

If you add to the direct impact like Covid-19 and Homeoffice also the indirect impact on the supply chains a clear yes. When we sourced the first individual parts to manufacture the first systems in 2021 there were many nasty surprises. Unfortunately, everything from cancellations of our orders to severely delayed deliveries was involved. Due to the semiconductor crisis, some electronics were no longer available at all and we were forced to carry out independent developments. This cost a lot of time, which you usually don’t have in a young start-up.

Which quality should you bring from your point of view as a founder?

As a founder you are constantly confronted with new challenges, where you do not immediately know the solution. You should bring a certain intrinsic motivation and curiosity, so that you do not get tired of these challenges. Of course, this requires a certain amount of stamina and endurance. Independence is certainly important, but you should still enjoy teamwork, because you can’t master the tasks alone. Last but not least, you should not see a start-up as a risk or existential threat, but as a unique opportunity and adventure.

Do you have any practical tips for other young entrepreneurs?.

Get in touch with other founders as early as possible and ask as many questions as you can. For example, we have written directly to other founders*innen before the founding and asked if you could meet for lunch or coffee. This not only gives you insights into details, but also anecdotes about challenges the founders had to solve. Learning firsthand that others also had to overcome many challenges initially is very reassuring.

What would you perhaps do differently from today’s perspective/ approach?

On the whole, we are very satisfied with the individual decisions. A big factor is and was with us always the time. Here we could certainly have put more focus on greater efficiency and effectiveness; some priorities we could certainly have set differently. In addition, a larger team is of course always helpful in distributing tasks better. At this point, we could have looked for new employees earlier and with more commitment.

What are your plans for the future? What are your next big milestones?

Our current focus is on building the company. In addition to optimizing manufacturing are looking for new employees, both for the actual manufacturing, but also for administration or sales. In addition, we are currently still delocalized in the office and manufacturing space, which is why we are looking for a suitable production building in Karlsruhe and surrounding area. Currently, we are focusing on the European market due to the high demand and the lower complexity. A next big step will surely be the development of new markets, preferably the US market.

Thank you very much for answering the questions! ☺.

PODCAST.

Listen in to our Podcast episode Foundation of the Month: qinu.