Machining glass as flexibly as plastic

25.11.2019

Ralf Stueber

Founder story

KIT scientists develop process for 3D printing of glass.

When people think of glass art, they often have an image in mind: glowing materials, heat, elaborate glassblowing. After all, the production of glass is a cultural technique that is around 5,000 years old. Even though modern production is a high-tech industry, its processing possibilities have long lagged behind those of other materials, especially solutions in the field of plastics.

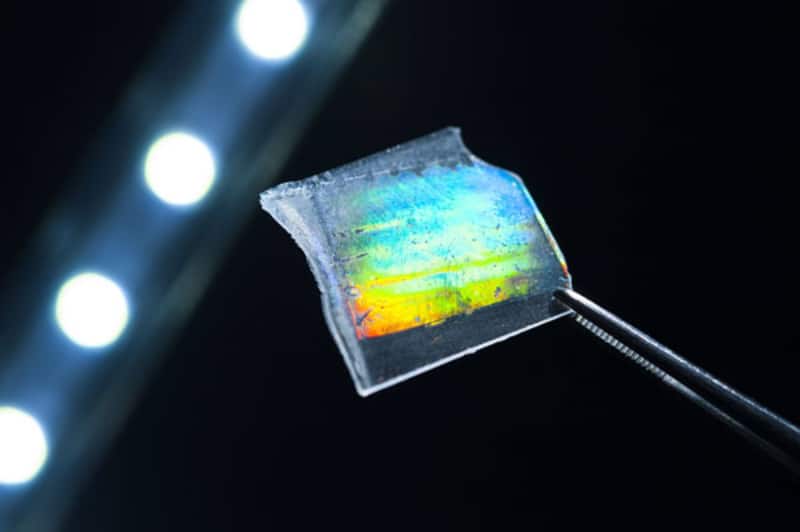

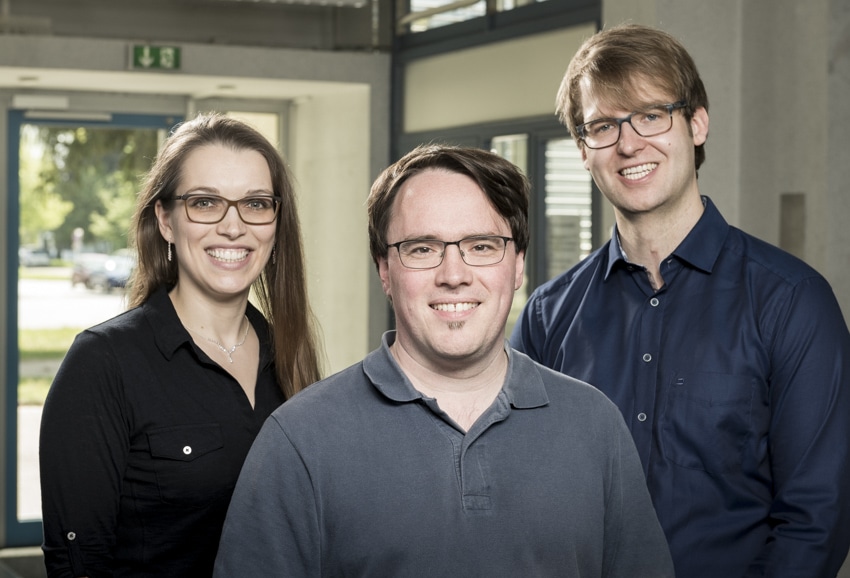

Three KIT materials scientists want to change this with their spin-off Glassomer GmbH, founded in early 2018. The three researchers and founders, Dr. Dorothea Helmer, Prof. Dr. Bastian Rapp, and Dr. Frederik Kotz, have developed a molding technique for industrial glass processing at the Institute of Microstructure Technology (IMT) at KIT over a period of several years, with which they can process quartz glass as variably as plastic. “Instead of heating glass to up to 1100 degrees Celsius and then shaping it or structuring parts of glass blocks, for example, by means of laser processing, we start with the smallest glass particles,” says Bastian Rapp. Glassomer’s process involves adding glass particles to the liquid plastic. “We then shape the mixture similar to a sand cake and harden it into a solid by heating or exposing it to light,” Rapp continues. This solid consists of 60 percent glass particles and 40 percent plastic. The polymers act like an adhesive that holds the glass particles in place and thus fixes the mold.

Even though Glassomer GmbH is now located at NeptunLab Freiburg, the founders are still closely connected to KIT. The preparation of the foundation was intensively accompanied by the team of KIT-Gründerschmiede.Currently, the team is looking for suitable partners from industry who share their vision of the glass manufacturing of the future. In the long term, the founders plan to establish a medium-sized manufacturing and development department that will further develop the technology but also manufacture products.